Our Technology

MineSense enhances mining operations by providing material characterization and classification, and identifying ore from waste at the earliest stage of the mining process

Heterogeneity: The Mine’s Reality

![]()

No two orebodies are the same. In fact, no two scoops of ore are the same. Heterogeneity – the material variation within a unit of rock – is a challenge faced by all miners. The composition of each unit of material you are mining and sending to the processing plant impacts efficiency, sustainability and profit.

Every mine has significant variability within each block which cannot be seen with the human eye, including volumes of higher grade and waste. Valuable ore is often thrown away or waste material is sent for processing, resulting in ore dilution and downstream productivity loss.

Without the tools to identify ore from waste early in the mining process, mines lose money and waste resources

Improving the profitability and sustainability of mining through first-of-its-kind technology

Our technology is a complete hardware and software System, enabled by proprietary algorithms, that measures and reports ore grade and ore characteristics in real time.

The Value of the MineSense System

Precise measurement of heterogeneity at the extraction face

Recover ore from waste

Remove waste from ore

Optimize mill recovery

Improve operations and sustainability performance that lower operating costs

Lower ore hardness as waste ore is rejected

Lower energy, water, and reagent consumption/tonne of metal produced

Lower CO2 emission per tonne of metal produced

Extend Life of Mine

Power of Ore Data Visibility

Value You Can See

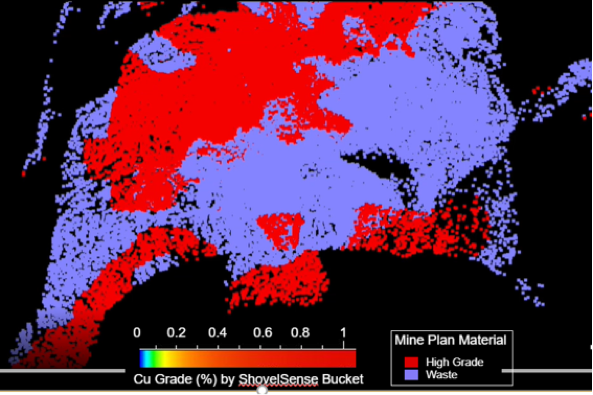

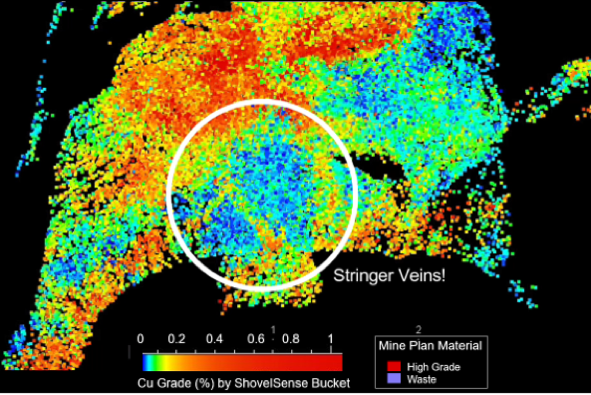

Visibility with MineSense

Grade Control Visibility without MineSense